High-quality elastic sensors made easy-to-use

“Making sensing easy”. This is a key term at ElastiSense Sensor Technology Our sensors help application developers and builders in a variety of different business areas add value to everything from factory automation, structural health monitoring, off-road vehicles, Medical applications, sports performance applications, and several other areas, often operating in rough environments or in positions that are difficult to attach sensors into.

Reducing costs during installation, operation, and maintenance are the immediate and obvious benefits when you utilize the elastic and durable ElastiSense Sensor Technology Sensors. However, both the operation data as well as current status data, provided by the sensors, will show almost invaluable over time as it paves the way for preventive maintenance, performance optimization, and health overview – especially when applied in locations and in machinery where other sensors cannot be used.

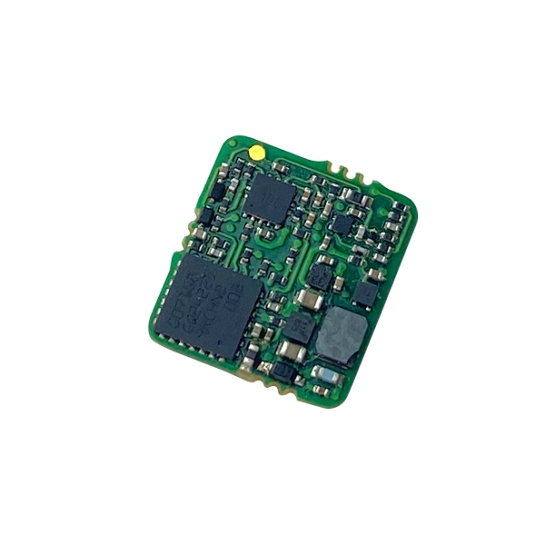

The most important features of ElastiSense Sensor Technology products are:

- Robust – highly resistant to shock, vibration, overload, and misalignment

- Accurate and repeatable – high accuracy due to capacitive sensing

- Versatile – can be configured to different needs in size, range, and electrical output.

Browse through our product range, be inspired, and do not hesitate to contact us – also with enquiries about customized solutions for your specific need or application. You can also make your purchase directly from our web-shop.